Thermal Transfer Technology is the Ideal Printing Solution for Flexible Packaging

Thermal Transfer Overprinting (TTO) was engineered as an advancement over traditional analog coding technologies like hot stamp and roller coders. TTO brings digital printing technology to flexible film packaging applications, common in many food industries. The printing process applies a code to a flexible film or label by using a thermal printhead and a thermal ribbon. The technology produces a very high resolution code onto the package that is easy to read and also helps ensure no degradation of the aesthetic quality of the packaging film artwork and design.

- Benefits

- Application Specifics

- Documents

High resolution print technology

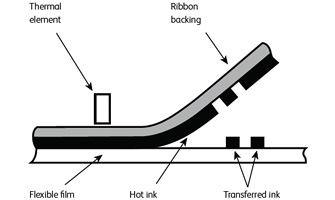

Thermal transfer printing uses a high resolution (300 dpi) thermal printhead and thermal transfer ribbon. The printer heats select elements on the thermal printhead to transfer the colored pigment in the ribbon onto the flexible packaging. This printing process can be used at speeds as fast as 400 packages per minute. In contrast to older analog technologies like hot stamping and roller coding, TTO’s high resolution printhead can also print logos, graphics and bar codes in addition to standard lot and expiry date information.

Economical solution for the packaging industry

Thermal transfer overprinters (TTO) are easily programmable, enabling the operator to quickly change from one message to another. This reduces the downtime and effort required to change dies and rollers associated with older hot stamping and roller coder equipment. Advanced TTOs use bi-directional ribbon drives to precisely control ribbon tension. This eliminates failure-prone mechanical solutions like dancer arms while simultaneously delivering ribbon savings by precisely controlling ribbon position.

Real-time variable data

TTO is a digital printing solution, which means it contains both a real-time clock and I/O communications capabilities. In addition to printing static codes, advanced TTOs have the ability to print unique data on each and every package. Depending on the production needs, TTO can print enhanced traceability information like packaging time stamps or, as an example, more advanced codes including unique serial numbers and associated bar codes.

Intermittent printing

Intermittent printing is used on lines where the packaging film moves in an intermittent motion (stop/start). The stop-time (dwell) within the cycle is used for printing. Using a signal from the packaging machine, the printer lowers the printhead onto the material and moves across the film to print. When complete, the printhead is raised and moves to the start position for the next package.

Continuous printing

On continuous flow lines, the packaging material is printed while the film is moving. The film runs between the printhead and a platen roller. After a start signal from the packaging machine, the printhead is pressed against the platen roller and printing is started. As the film is pulled through the filler, the printer prints on every package. A stop print signal causes the printhead to be raised.

Ribbon

TTO ribbon has a very thin layer of dry ink on one side of a polyester film and a suitable printhead lubricant on the other side. The ink layer is either a resin material or a mixture of wax and resin materials. The optimal ribbon will depend on the individual application and the exact coding requirements.

Contact Us

Mobile (UAE only):

+971 800 03 210 37

Mobile (International and Whatsapp):

+971 50 127 8532