The essential guide to laser safety: How to ensure beam shielding and fume extraction in 2026

Videojet Knowledge Hub Team

laser, safety, beam shielding, fume extraction

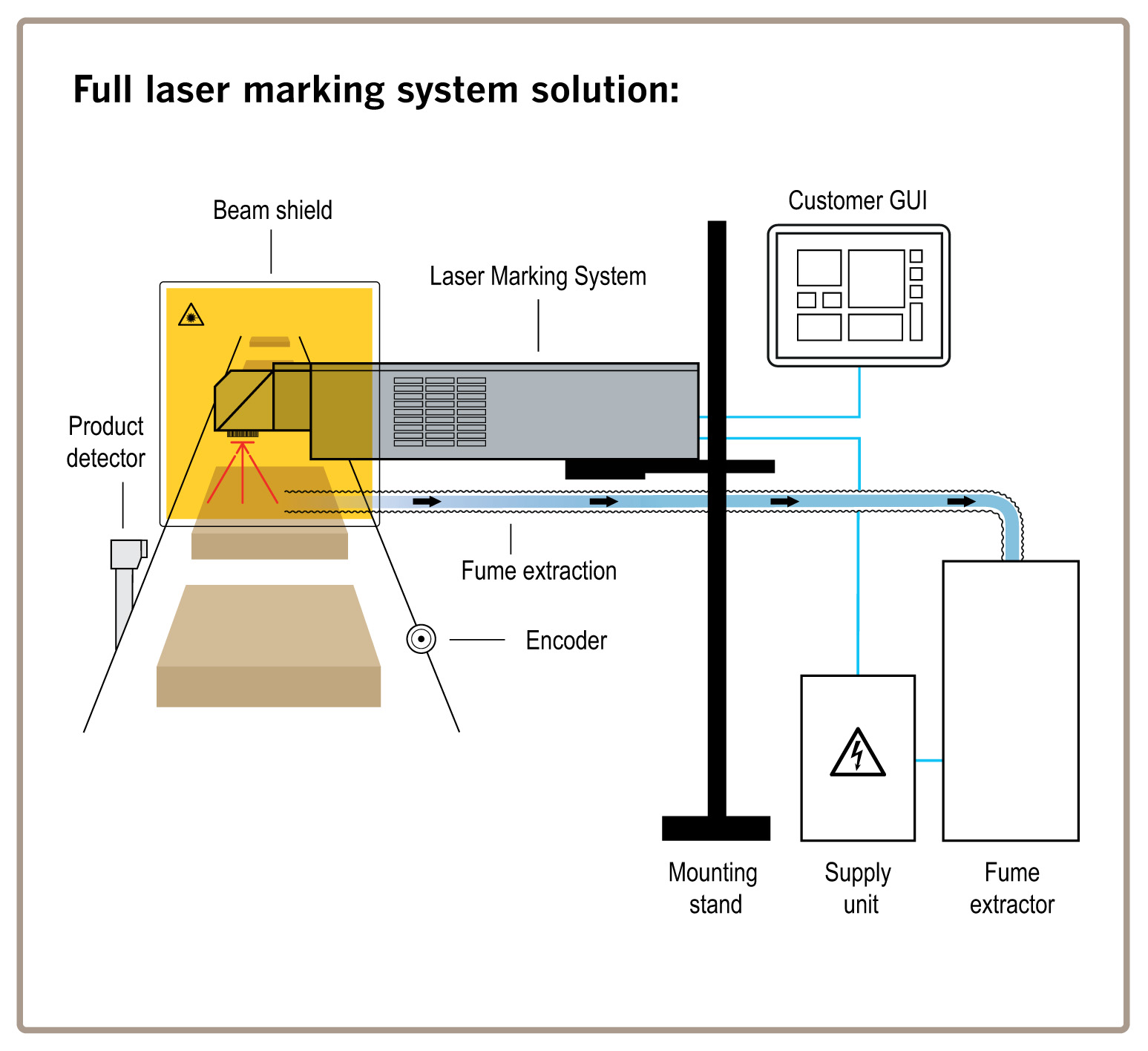

Laser safety is the practice of preventing harm when using laser systems by controlling beam exposure and air quality. It covers two critical areas: beam shielding to contain laser paths and fume extraction to remove hazardous emissions. Choosing the right safety measures is essential because they help protect people, ensure compliance, and maintain operational efficiency.

What is laser safety and why does it matter?

Laser technology has revolutionized countless industries with its precision and efficiency. Yet, as with any powerful tool, understanding and implementing safety measures is paramount. The two most critical components are beam shielding and fume extraction.

Why is beam shielding important?

Beam shielding is an essential component of laser safety. Its purpose is to contain the laser’s path, helping to prevent accidental exposure to personnel and avoid damage to surrounding equipment.

Here’s why it’s vital:

- Protecting Personnel: Properly shielded lasers significantly reduce the risk of accidental exposure, which can result in eye damage or skin burns.

- Safeguarding Equipment: Properly shielded lasers ensure zero risk of collateral damage to other machinery and infrastructure within the workspace.

- Ensuring Compliance: Beam shielding helps to meet legal safety requirements, thus avoiding potential fines and maintaining a company’s reputation for responsible practice.

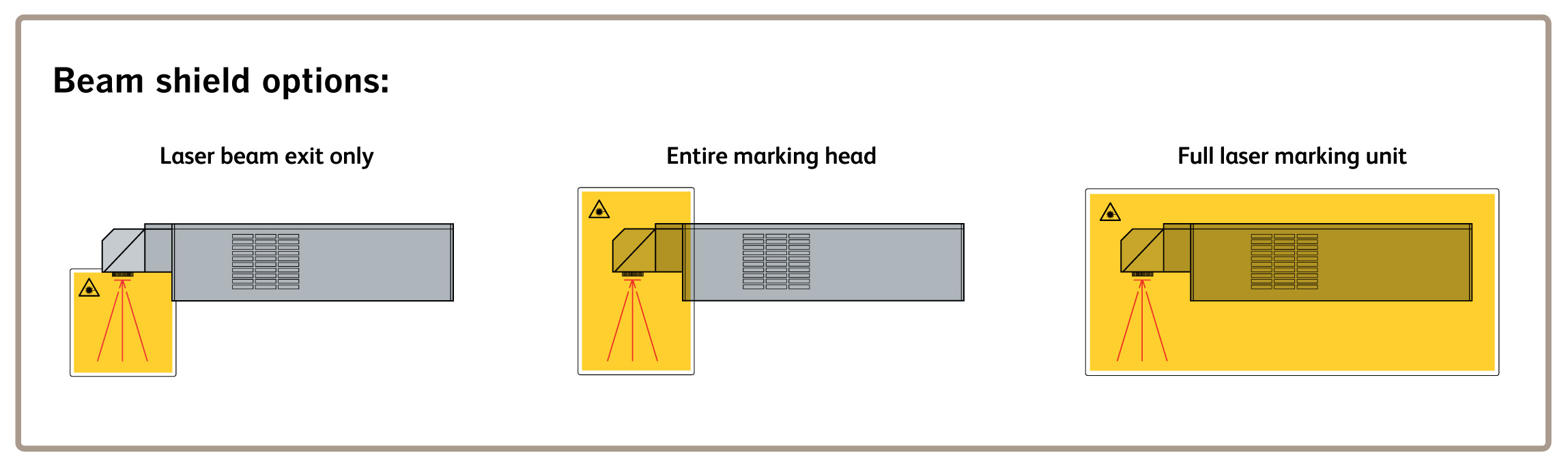

What types of beam shielding are available?

The laser industry provides a spectrum of beam shielding solutions, each designed to cater to different operational needs and laser types. Options include:

- Exit-only shielding: Best suited for applications requiring focused protection, exit-only shielding prevents the laser beam from extending beyond the immediate work area.

- Entire head shielding: For situations where operator proximity to the laser is unavoidable, entire head shielding offers an added layer of protection, enclosing the laser head completely.

- Full unit protection: In environments where comprehensive safety is paramount, full unit protection ensures that the entire laser apparatus is shielded, delivering peace of mind across all operational aspects.

Why is fume extraction critical for laser safety?

The process of laser material interaction often produces fumes and particulate matter that can compromise workplace air quality and pose health risks. An effective fume extraction system is a non-negotiable component of a safe working environment, essential for:

- Preserving workplace health: Extraction systems play a pivotal role in removing hazardous fumes, thereby maintaining a safe and healthy air quality for employees. This is not only a matter of safety but also of worker comfort and productivity.

- Maintaining laser precision: Accumulation of fumes and particulates can interfere with laser operation, affecting the quality and consistency of the work. Fume extraction systems ensure that the path of the laser remains clear and the workspace clean, thereby upholding the precision of the laser.

- Regulatory adherence: Many industries are governed by strict regulations regarding air quality and emissions. Effective fume extraction systems are critical for compliance with these regulations, protecting businesses from potential fines and legal action.

What are best practices for fume extraction maintenance?

To guarantee the effectiveness of fume extraction systems over time, a rigorous maintenance routine is essential. This includes:

- Scheduled system inspections: Frequent inspections can identify early signs of wear or damage, allowing for preemptive maintenance and repairs.

- Timely filter replacements: Regular filter changes, based on the manufacturer’s guidelines or operational demand, are crucial for maintaining the system’s extraction efficiency.

- System component cleaning: Removing buildup from all parts.

How do you choose the right laser supplier?

Look for experience, product range, quality standards, customization options, technical support, competitive pricing, and innovation. A good supplier should also provide guidance on beam shielding and fume extraction.

Checklist for choosing the right laser supplier

| Factor | What to look for |

| Experience and reputation | Proven track record, positive reviews, and industry credibility |

| Range of products and services | Comprehensive laser solutions including beam shielding and fume extraction; plus installation, maintenance, and training |

| Quality and reliability | Compliance with safety standards, certifications, durable and efficient systems |

| Customization and flexibility | Ability to tailor solutions to unique operational needs |

| Technical expertise and support | Knowledgeable team, responsive customer service, guidance during implementation |

| Cost and value | Competitive pricing with strong ROI; prioritize value over lowest cost |

| Innovation and technology | Commitment to R&D, cutting-edge solutions, future-proof technology |

Conclusion: How can you embrace laser safety effectively?

In conclusion, prioritizing fume extraction and beam shielding isn’t just about compliance, it’s about creating a culture of safety and excellence in your operations. By implementing these practices, you’re not only safeguarding your workforce and infrastructure but also driving innovation and success.